Over the course of more than 30 years, I have had numerous achievements, both in large and small corporate settings as well as my own entrepreneurial adventures. Manufacturing, Telescopes, Astronomy, Computers and Fountain Pens have always been my passion (what a geek!). Anyway - here is just a fraction of my personal history:

![]()

Education:

Kingswood Preparatory School, West Hartford, CT

Boston University, Boston, Ma

1974-1981

General Manager - Criterion Scientific Instruments

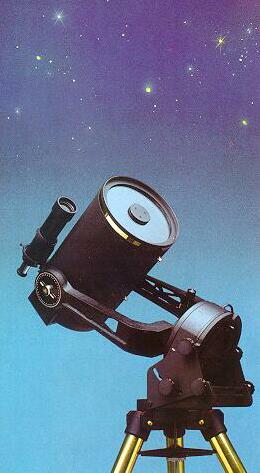

Criterion Scientific Instruments made precision optics and optical instruments for both consumer and government use. Some of the products were Microscopes, telescopes, and various other specialized and custom made optical systems and precision optical components. After a few years, I became a well known in this field and published numerous technical articles in various trade journals and also consumer magazines specific to the industry such as Popular Astronomy. As General Manager, I had bottom line responsibility for the entire manufacturing operation.

In addition to daily management duties, one of my primary responsibilities was to develop and implement computer information systems technology at the plant. This involved setting up and maintaining computers and computer systems for all phases of the manufacturing facility including inventory control, accounting and quality control. Back in those days, PC's were scarce and expensive and ran only DOS - so this was not an easy task.

Another major accomplishment in my career was the

implementation of computerized machine tools in the machine shop. This extremely

high tech machinery was made by SEIKI Corporation and required complex

programming to automatically produce both two and three axis component parts

with extreme degrees of precision in a fully automated production environment..

After successfully graduating from the SEIKI Corporation Computer Programming

School, I became the master programmer for all machine parts made at the plant.

This was only temporarily until all the parts were programmed and other

technicians were trained and all procedures documented - but the

experience was invaluable. As computer technology moved ahead, I was responsible for implementing the

latest technology in every area of the Company - Machine Shop, Optical Shop,

Accounting and Administration.

Another major accomplishment in my career was the

implementation of computerized machine tools in the machine shop. This extremely

high tech machinery was made by SEIKI Corporation and required complex

programming to automatically produce both two and three axis component parts

with extreme degrees of precision in a fully automated production environment..

After successfully graduating from the SEIKI Corporation Computer Programming

School, I became the master programmer for all machine parts made at the plant.

This was only temporarily until all the parts were programmed and other

technicians were trained and all procedures documented - but the

experience was invaluable. As computer technology moved ahead, I was responsible for implementing the

latest technology in every area of the Company - Machine Shop, Optical Shop,

Accounting and Administration.

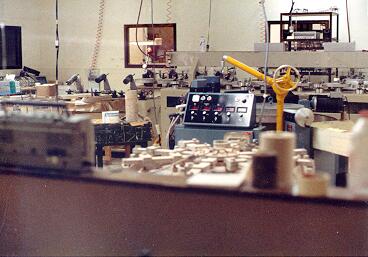

Here is a

photo of a small portion of the Optical Shop showing some of the most

sophisticated computer controlled equipment in the country at the time - much of

which was proprietary and designed and engineered in house. It was taken behind

a window because the entire room was a "clean room" environment -

sealed against dust, moisture, temperature variations, etc. In the shop, we

produced optical components to manufacturing tolerances of millionths of an

inch!! In fact, the optics were so precise, their accuracy could only be

measured by laser light. We routinely produced optics that were accurate

to 1 tenth of one wavelength of light. I had a very large part in developing the

production methods by which this was done in volume on a daily basis (that resulted in

a US Patent)

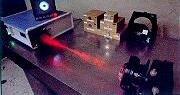

and special testing devices like

the special laser collimator I built pictured below.

Here is a

photo of a small portion of the Optical Shop showing some of the most

sophisticated computer controlled equipment in the country at the time - much of

which was proprietary and designed and engineered in house. It was taken behind

a window because the entire room was a "clean room" environment -

sealed against dust, moisture, temperature variations, etc. In the shop, we

produced optical components to manufacturing tolerances of millionths of an

inch!! In fact, the optics were so precise, their accuracy could only be

measured by laser light. We routinely produced optics that were accurate

to 1 tenth of one wavelength of light. I had a very large part in developing the

production methods by which this was done in volume on a daily basis (that resulted in

a US Patent)

and special testing devices like

the special laser collimator I built pictured below.

1981-1986 Vice

President & General

Manager Bushnell Div. of Bausch & Lomb

As VP/General Mgr of the Bushnell Division of Bausch & Lomb, I had bottom

line responsibility for every aspect of the company, including budget,

marketing, manufacturing, Human Resources, plant safety, administrative, etc.,

etc.

company, including budget,

marketing, manufacturing, Human Resources, plant safety, administrative, etc.,

etc.

1986-1988 Vice

President of Marketing Bushnell Division of Bausch & Lomb

In late 1985, in preparation for Halley's Comet, a decision was made by senior management for me to transition my operational responsibilities to a new Plant Manager so that I could focus entirely on what we perceived to be the largest potential marketing tool ever to hit the telescope market - a once in a lifetime comet. As such I was made VP of marketing with the express understanding that I would always be available to assist with plant operational issues on a consulting basis. Why me? Because it would take an expert in both the proper equipment to use as well as how to use it to effectively market the instruments we wanted to sell, which included a special line of telescopes, binoculars and telephoto lenses. And, I was one of the few people having the complete knowledge of every technical aspect of viewing and photographing this amazing comet - which is exactly what would be needed to entice the general public into buying our optical products. I began holding press conferences (the most memorable was at the "Tavern on the Green" in Central Park, NY) and made numerous TV appearances to talk about viewing the Comet. I also recruited other renowned experts in the field to be spokespeople for our products, endorse them, and even be on user groups to tell us what the public might want the most. My marketing plan was simple, subtle and quite effective: Myself and several other experts produced a remarkable presentation on the comet and how to see it and photograph it that was interesting, educational and really held your attention. We then booked seminars at major photo stores throughout the US that carried our products, The seminars were advertised heavily in the local papers - we paid for the seminars which were FREE to the public and also paid for the ads. Hundreds would come out at night to these seminars and we would present the show - then subtlety pitch our products by taking everyone outdoors where the scopes were setup for them to look at and through - in some cases we let everyone take their own picture of the moon through the scope. We never pushed the product on them - we educated them and then showed them the ideal product for the task they just learned about and it then sold itself. We sold thousands of units - breaking all previous sales records. We made money - and so did the camera stores hosting the seminar. The camera stores would also benefit by people buying cameras and other peripheral equipment just because it was there. My plan was a huge success and I received a substantial bonus for my efforts. It was hard work though - I spoke all over the country in major cities throughout the US.

Ahhh - but all

good things must come to an end sometime: In December 1997 a decision

was made by Bausch & Lomb to close this facility. The decision had nothing

to do with profitability or performance but was instead a well planned decision

by senior management to close all precision manufacturing facilities

within the corporation and focus more on contact lenses, solutions and the

drugstore markets. At one time Bausch & Lomb was noted for its precision manufacturing

and I am proud to have been a part of that. Today it is known only for its

sunglasses, contacts and solutions - which was exactly what the long term (25

year) plan called for when they made the plant closing decision. Although I was offered an

executive management position in other locations, I was unwilling to move out of state.

1988 1994 President and CEO Harvest Time Vitamins, Inc

As

I said earlier, I spent a

lot of time in California at our divisional headquarters. I also played a lot of

golf there at a local country club in my leisure time after work, weekends, etc.

At the club I played a few times with the founder and CEO of Vita Fresh Vitamin

CO - a 30 Million dollar Vitamin company. One day he told me he was going to

sell his company to Your Life Vitamins - a 500 million dollar Co. (which he

subsequently did). He said that his company had a smaller direct mail entity

called Harvest Time. They used Harvest Time for direct sales to consumers that

did not have local stores to go to. He said that the new company had no interest

whatsoever in direct marketing via mail order (they were a huge national

marketing chain). I had just been forewarned by management at my company that

they would be closing our division - so the timing was perfect!!! I struck a

tentative deal over dinner that night to purchase Harvest Time Vitamins and

toured "my soon to be new company" the very next day! Did I know squat about

Vitamins?? Hell no - what's a vitamin??? But I did know how to manage and run a

company and market a product - I had years of training doing just that. And I

also knew how to learn and study and become a Vitamin expert - which I did.

Within a year I was developing custom formulas for specific purposes - some of

which became best sellers and were marvelously popular such as the one shown

below at right- MEGA MIGHT. I maintained a direct mail campaign and did my own

mass mailings of my 32 page catalog. I did all my own advertising, designed my

own catalogs and other direct marketing literature, and was one of the first

ever places on the web (when it first became available) to buy p

As

I said earlier, I spent a

lot of time in California at our divisional headquarters. I also played a lot of

golf there at a local country club in my leisure time after work, weekends, etc.

At the club I played a few times with the founder and CEO of Vita Fresh Vitamin

CO - a 30 Million dollar Vitamin company. One day he told me he was going to

sell his company to Your Life Vitamins - a 500 million dollar Co. (which he

subsequently did). He said that his company had a smaller direct mail entity

called Harvest Time. They used Harvest Time for direct sales to consumers that

did not have local stores to go to. He said that the new company had no interest

whatsoever in direct marketing via mail order (they were a huge national

marketing chain). I had just been forewarned by management at my company that

they would be closing our division - so the timing was perfect!!! I struck a

tentative deal over dinner that night to purchase Harvest Time Vitamins and

toured "my soon to be new company" the very next day! Did I know squat about

Vitamins?? Hell no - what's a vitamin??? But I did know how to manage and run a

company and market a product - I had years of training doing just that. And I

also knew how to learn and study and become a Vitamin expert - which I did.

Within a year I was developing custom formulas for specific purposes - some of

which became best sellers and were marvelously popular such as the one shown

below at right- MEGA MIGHT. I maintained a direct mail campaign and did my own

mass mailings of my 32 page catalog. I did all my own advertising, designed my

own catalogs and other direct marketing literature, and was one of the first

ever places on the web (when it first became available) to buy p

Harvest Time was a fascinating entrepreneurial business experience that you could not possibly learn about in any school no matter how long you stayed in school studying business courses: It involved a real life experience of running absolutely every aspect of a real life business: Marketing, Advertising, Customer Service, Accounting, Finance, Production, Shipping and anything and everything else in between!.

But in late 1993, I realized that I had experienced all the growth that my business could stand without going to the "next big step" which was probably going to be venture capital. I was going to have to invest far too much to take my business to the next level - and I did not want any partners (although I had many people who wanted "in" on what they saw as a great business opportunity). But I made a tough personal decision to sell Harvest Time and move on to another entrepreneurial adventure - Computer Technology.

1994

1998 Computer Consultant and Network Engineer

Utilizing PC technology from

my previous work experience and certifications, I started my own Computer Consulting company and provided my PC

expertise to clients in the Greater Hartford Area. I upgraded and

repaired their systems as needed and kept them running smoothly. I designed,

implemented and maintained complete office networks for clients and sold and

maintained all types of hardware and

software for various businesses in the area. I also spent considerable time

working as a Network Engineer for RHI Computer Consulting in Hartford, CT.

Utilizing PC technology from

my previous work experience and certifications, I started my own Computer Consulting company and provided my PC

expertise to clients in the Greater Hartford Area. I upgraded and

repaired their systems as needed and kept them running smoothly. I designed,

implemented and maintained complete office networks for clients and sold and

maintained all types of hardware and

software for various businesses in the area. I also spent considerable time

working as a Network Engineer for RHI Computer Consulting in Hartford, CT.

1998 -

2000 IT

Technical Support Manager

In 1997, RHI Consulting asked me to help on on a "30 day temporary assignment". That month turned into years and I became the IT Technical Support Manager for a large Health Care System. In this position, I was responsible for over 4000 networked devices including PCs, printers, servers and gateways for both LAN and WAN environments.

2000 - Present - Director of IT Technical Services

As Director of Technical Services for a large Health Care System my current responsibilities include Computer Desktop Support, Network Infrastructure, Telecommunications, Multimedia Services and Clinical Engineering Departments.

In my previous business experiences detailed above, I always made numerous improvements in efficiency and technology. I plan to continue on in the same tradition of excellence in my current role.